Posted by The Alchemy Editorial Team on 27th May 2016

The Process of Alchemy (Part 1 – Design)

How is Alchemy England jewellery made?

Well, it doesn’t just appear out of a machine on the other side of the world, as many people quite often assume!

The reason that Alchemy is so different and special, is that it is actually all developed from scratch and hand made by a skilled and dedicated team of professional enthusiasts in Leicester, England. For nearly 40 years, Alchemy have been designing and creating original works of art for the alternative cultures and distributing them to fans in over 60 countries around the world, from all over Europe and the USA, to distant cultures such as Brazil, Israel, Japan and China.

The process always begins in our studios, with just an idea – a subject, a story or an event to portray, or sometimes just an eccentric vision in the imagination of one of our avant-garde creative team! Inspiration can come from an historical anniversary, a book, a visit to an art gallery, museum or Mediaeval town centre, a revived legend or a discovered folk-tale, etc. Whatever the source, once our creative team’s imaginations have their teeth into a subject, the figurative story-telling begins! A unique blend of deep and thorough research and creative artistic license eventually emerges as a singular design of distinct Alchemy flavour.

The resulting concept is then usually hand drawn, to develop its design and and then convey the impression to the rest of the team and to the sales crew, who best know our customers.

From the hundreds of ideas dreamed-up by our aberrant artists and designers each year, a balanced, small selection is chosen for inclusion in each season’s collection. Each design must then be thoroughly thought through in every aspect and checked by every department to ensure the practicality of manufacture balanced with its aesthetic excellence. When everybody in the process is finally satisfied, the design is completed in minute detail and drawn to perfection.

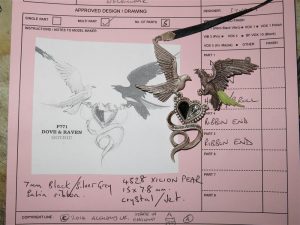

A development card is then made-out for each selected design, which will include all the details necessary to make each final piece, such as its size, its specific finish and its choice of findings and crystals, etc.

Many models will often comprise both hand sculpting and precise and finely detailed model components requiring micro-engineering, all of which is done in our self-contained, Leicester workshops. Such miniature components, therefore, will need their own additional, highly technical, computer drawings for them to be precision-made for incorporation into a finished model.

Next month, Part 2 will explain our process of Model Making.

The Alchemy Editorial Team

www.alchemyengland.com